Aarkay Explo Print SD - Emulsion : L3 Online Post Printing Scanning, Packaging & Rejection SPM System

Benefits:

▪ Speed from 70 – 90 cartridges per minute per channel. ▪ Can go to upto four channels maximum, i.e. (300 – 400 CPM) ▪ Low Cost of Printing < 4.5paise/Cartridge. ▪ Negligible Losses/Wastage less than 3-4%. ▪ Works on Two Modes – With Rejection & Without Rejection ▪ Automatic L1 sticker Printing system ▪ Easy to Maintain, Implement & Operate. ▪ PESO - SETT Norms Compliance - Meets regulatory norms by mapping and documenting L3, L2, and L1 data in structured CSV format & supports seamless audit readiness with accurate, real-time data. ▪ CSV Output for System Integration/Upload to PESO Portal ▪ Automatically generates a structured CSV file with complete L1–L2–L3 mapping, easily importable to ERP systems or can be uploaded directly to PESO portal.Key features:

▪ Complete SS body to prevent corrosion. ▪ FLP Motors. ▪ Outdoor IP65 Power Cabinet with UPS for Printer & Scanning System. ▪ VFD and other controls. ▪ User Friendly system.Solution Overview:

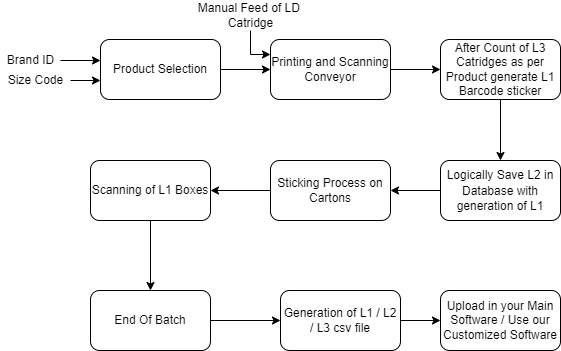

L1 Print Process and Mapping of L3 – Offline Pre-Printing of L1 Carton Sticker will be done and it will pasted before filling the cartons, and the system counts the no. of L3 as per the Brand and Size code, When no. of L3 barcodes is equal to the count required to fill a carton as per std., and records the L3 unique nos. against L1 and updates the database. L1 Barcode is mapped with the L3’s Barcode cartridges which goes in to the carton/box. After completion of the batch the L1 – L3 mapped data is moved or synced to the central database server for RE2 generation and other Storage and Dispatch processes. It streamlines production while reducing downtime and training efforts, making it an efficient, cost-effective, and user-friendly solution for the explosives manufacturers.

📞 Contact us to streamline your production operations!